Blood plasma fractionation:

With SIMATIC PCS 7 and SIMATIC BATCH, the blood plasma fractionation process is mapped and controlled with the required high degree of efficiency, quality and performance.

Blood plasma fractionation is the process of extracting proteins from human blood plasma. This process runs in several phases and takes place under strict guidelines and strictly controlled environmental conditions.

SIMATIC PCS 7 multi-project according to ISA-88 and offers a template in which all typical components, their control and regulation, the necessary logic and locking as well as the visualization are available. The structure is modular and based on standardized technical functions and measuring point types.

CIP - Cleaning in Place:

If you look at a plant for the production of food or pharmaceutical products and their technical processes, you will see that certain process steps, procedures and devices are repeated in the same or similar form. An important process in this context is the automated cleaning of the equipment and plant components. This process becomes more and more important as the size of the system increases, since manual cleaning is no longer possible. An efficient process is the "Cleaning in Place" process, or CIP process for short. The CIP process enables equipment and plant components to be cleaned on site. Disassembly is not necessary. This type of automated cleaning also saves valuable working time.

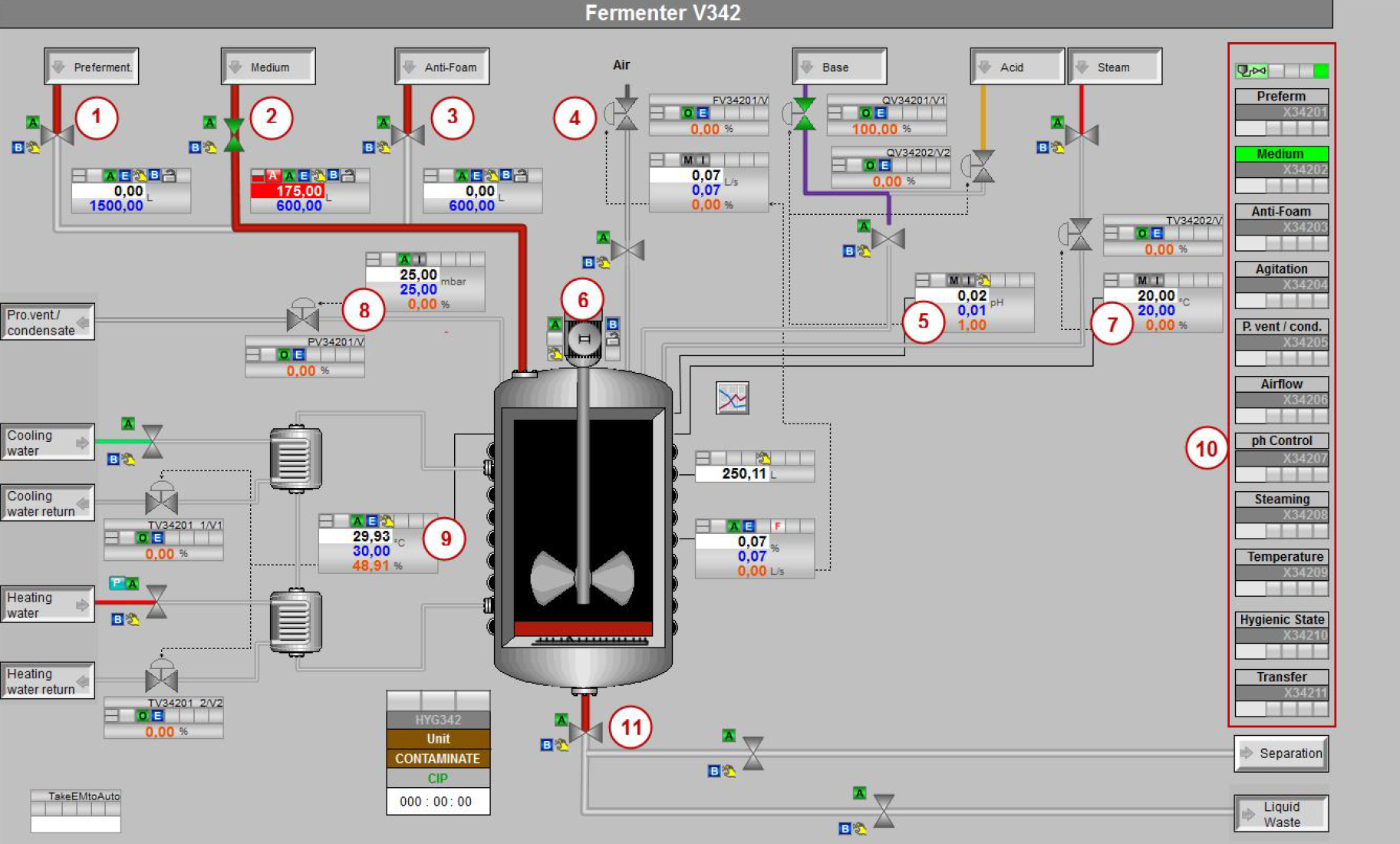

Fermentation:

In this application, SIMATIC PCS 7 and SIMATIC BATCH are used to map and control the fermentation process with the required high degree of efficiency, quality and performance.

Fermentation is the process of cultivating organic matter. This process runs in several phases and takes place under strict guidelines and strictly controlled environmental conditions.

SIMATIC PCS 7 multi-project according to ISA-88 and offers a template in which all typical components, their control and regulation, the necessary logic and locking as well as the visualization are available. The structure is modular and based on standardized technical functions and measuring point types.

Freeze Dryer:

SIMATIC PCS 7 and SIMATIC BATCH are used to map and control the freeze drying process with the required high degree of efficiency, quality and performance.

Freeze drying (lyophilization) is an important step in the manufacture of many pharmaceuticals and is playing an increasingly important role in the life sciences industry.

This is a particularly gentle drying process that takes place in several complex steps and has a significant impact on the quality of the end product. In order to achieve constant product quality, the necessary process conditions and parameter values must therefore be guaranteed throughout the entire process.

SIMATIC PCS 7 multi-project according to ISA-88 and offers a template in which all typical components, their control and regulation, the necessary logic and locking as well as the visualization are available. The structure is modular and based on standardized technical functions and measuring point types.